News

Contact Us

|

Zhang Rui |

|

13829213667 |

|

0769-82105186 |

|

kefu@xienuosujiao.com |

|

Room 201, building 3, No. 7, Xiegang Xincheng 1st Road, Xiegang Town, Dongguan |

What auto parts can pa modified plastics do?

Time:2020-03-04

Views:89

First of all, we need to know why the automobile body and other accessories should be made of plastic - the lightweight of the automobile. This concept means that on the premise of ensuring the strength and safety performance of the automobile, the servicing quality of the automobile should be reduced as much as possible, so as to improve the power of the automobile, reduce fuel consumption and reduce exhaust pollution. However, plastic can perfectly replace the heavy metal to meet the requirements.

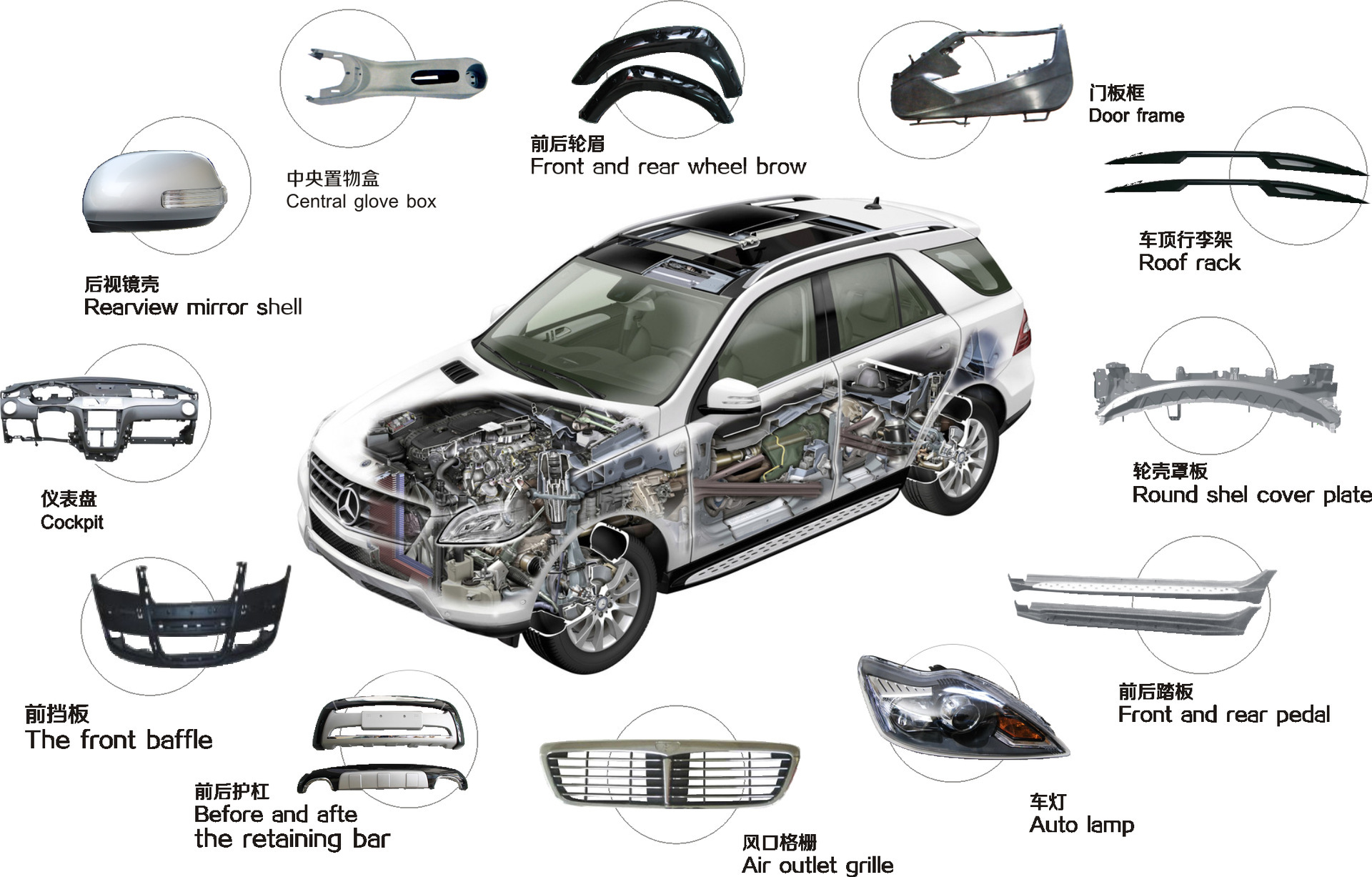

PA modified plastics have high performance, which can not only replace metal materials, but also have better strength and heat resistance than general-purpose plastics (such as PE, PP, PVC, ABS and other thermoplastics). Therefore, PA modified plastics are mainly used in automotive interior parts, exterior parts and functional structural parts.

The use of PA modified plastics in exterior fittings can reduce the dead weight of vehicles, which is one of the most effective measures to reduce vehicle emissions and improve combustion efficiency.

According to the survey, the fuel consumption can be reduced by 6% ~ 8% if the mass of the vehicle is reduced by 10%. 100kg plastic is functionally equivalent to 200~300kg metal parts. Therefore, it can be inferred that 750L fuel can be saved when the car travels an average of 150000 km.

In terms of safety, the impact resistance of PA modified plastic is not inferior to that of metal, or even higher than that of metal. Making instruments, seats, headrests and other products with elastomers and foamed plastics that can absorb impact energy and vibration energy can reduce the damage to human body during collision and improve the safety factor of automobiles. Structural parts are mostly made of high-strength engineering plastics. For example, plastic is used as some parts on the fuel tank, engine and chassis to reduce the mass, reduce the cost and simplify the process.

PA modified plastics are also used for automobile engines and peripheral components. The main varieties are gfp:a6, gfpa66, reinforced flame retardant PA6 and other products.

As the surrounding components of the engine are mainly heating and vibration components, most of the components are made of glass fiber reinforced nylon. This is because nylon has good comprehensive properties. The main properties of nylon modified with glass fiber have been greatly improved, such as strength, product accuracy, dimensional stability, etc.

PA modified plastics are widely used in automobile intake manifold. In addition, modified nylon is generally used as the preferred material for engine cover, engine decorative cover, cylinder head cover and other components. Compared with metal materials, the weight of cylinder head cover is reduced by 50% and the cost is reduced by 30%. In addition to engine parts, other stressed parts of the car can also use reinforced nylon, such as oil filter, wiper, radiator grille, etc.

Auto parts are the largest consumer market of PA modified plastics, accounting for more than one third of the total consumption. With the continuous improvement of automobile performance requirements and the development of PA modified plastics, PA modified plastics for automobiles are increasing year by year. The components that can be made of PA modified plastic on the car include air filter, housing, fan, wheelhouse, deflector, interior decoration, water storage device cover, line card, various interior electrical connectors, etc.

Wechat scan

Wechat scan